Smart Factory

- Concept

-

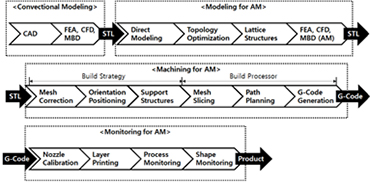

3D model slicing software for additive manufacturing

- Main Features

-

Technology for domestic 3D printing slicer engines that can replace overseas slicers (e.g. Cura)

3D printer code-generating core engines and plug-in designs

Tailored slicer UI for individual 3D printer manufacturers (e.g. custom properties window)

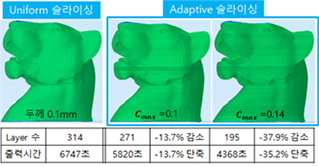

Optimal layer thickness analysis-based adaptive slicing

Automatic 3D model orientation detection engine

40% improved printing speed than Cura’s Uniform Slicing with same print quality (*Only when 3D printing equipment is optimized with adaptive slicing and auto rotation technology)

A shape optimizer and path optimizer, in addition to all other requirements for customizable slicer software, enable companies to accumulate their technical know-how by finding their own best shapes and printing paths.

- Applications

-

3D printing

- Concept

-

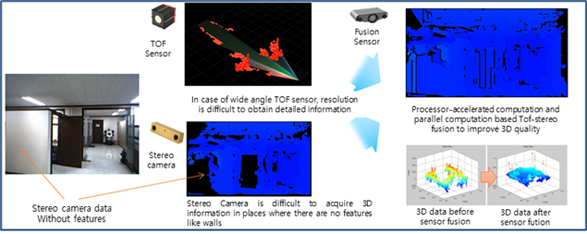

A 3D indoor/outdoor environment recognition sensor for low-cost robots using a wide-angle time of flight (TOF) sensor and a stereo camera

- Main Features

-

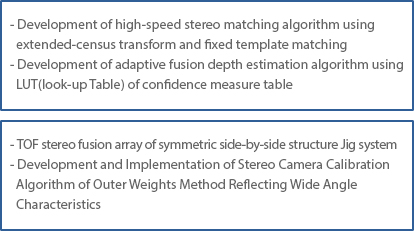

A high precision HD wide-angle sensor based on the precise calibration of a stereo camera and a TOF sensor

A wide-angle TOF-stereo integration algorithm

A calibration solution for a TOF-stereo fusion sensor

A Graphics acceleration processor-based algorithm

A TOF-stereo camera fusion sensor that collects high precision high definition environment information and models the environment for the driving, operation and control of a robot

- Applications

-

RobotAutonomous driving

- Concept

-

3D simulation-based problem solving and process improvement services for manufacturing optimization

- Main Features

-

Digital virtual factory construction using a 3D content library

3D simulation synchronization in PLC programs and human-machine interfaces (HMI) for virtual and real factories

Real-time control of an actual manufacturing site with a small rentable manufacturing process controller system

Applicable to a system to interface with a variety of PLCs (Mitsubishi, Siemens, Rockwell, LS, etc.)

Solid Edge and STEP reference content that can be edited and used in numerous CAD tools

- Applications

-

ProductionVirtual manufacturing

- Concept

-

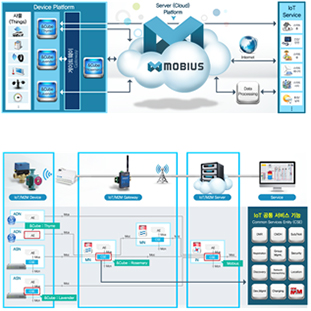

World’s first open-source IoT platform that is oneM2M-compliant and supports a variety of standard platforms

- Main Features

-

OneM2M certified

Provide open sources for outlets/gateways (&Cube) and servers (Mobius) for IoT system development

Enable scalable integrated IoT service environment by connecting various global standard platforms (including OCF and LWM2M)

Useful for industrial use with high reliability and real-time operability

Search, manage and synchronize with numerous video streaming services

Semantic information storage and management features for meaning-based data synchronization

- Applications

-

Smart city Smart factory Smart farm Smart logistics

- Concept

-

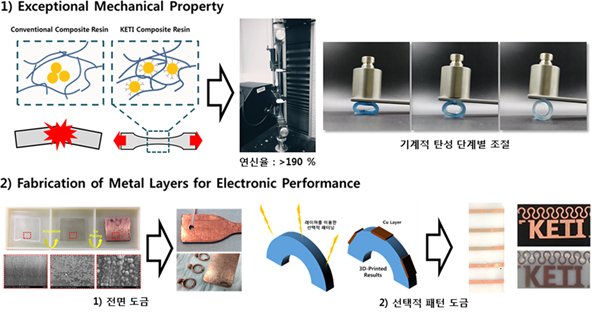

Composite materials and parts for custom 3D printing with a high resolution of 30μm

- Main Features

-

Organic-inorganic hybrid oligomer design and composition techniques

A new hybrid oligomer-based photocurable composite

Processing techniques for 3D printing materials with high elasticity and stiffness

Outstanding mechanical properties (percentage elongation: ~190%, tear resistance: 31Kg/cm, hardness: 91A) for wearable device applications

A functional inorganic filler inside and plating patterns on the surface of the material to support the electronic performance of wearable devices

- Applications

-

Wearable electronic component / deviceBiomedical parts 3D printing

- Concept

-

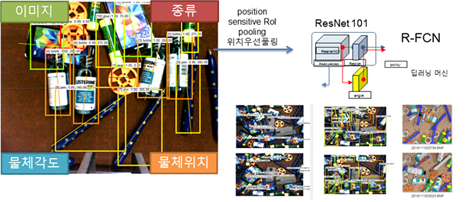

Deep learning algorithm-based robotic technology for grasping and handling of a specific object from a pile of mixed objects

- Main Features

-

AI-based bin-picking that is useful for general and factory logistics

Collect data of 3,000 picking activities daily through an automatic learning system

Collect virtual learning data from 3 million or more picking simulations

A lightweight robot control module with a collision detection sensor

A self-learning data collection module using automatic configuration of empirical data acquisition

Build a massive amount of high-quality learning data collection using the simulator’s data acquisition feature

- A 95% recognition and 90% picking success rate using massive deep learning data

Cost reduction by half for a brushless DC motor (BLDC motor) and by one-third for a joint module through domestic production of a robot control module

- Applications

-

Logistics centerIndustrial robot

- Concept

-

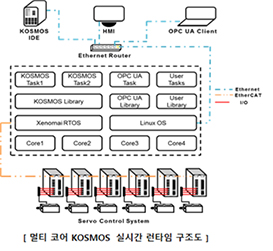

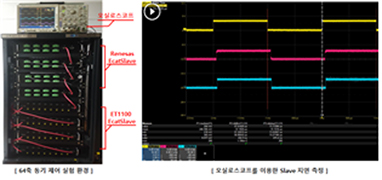

A Korea Open Source Motion System (KOSMOS)-based universal motion controller for manufacturing automation

- Korea Open Source Motion System (KOSMOS): a standardized Korean open source motion control platform that provides high-speed real-time control, industrial networking, motion library, safety, integrated system information processing, and scalability

- Main Features

-

System resource management for multi-platform implementation

A 500μs task frequency, 64-axes 100Mbps network-based PLCOpen TC2 motion control platform

An open source software-based standardized motion control software platform

- Applications

-

ManufacturingRobot

- Concept

-

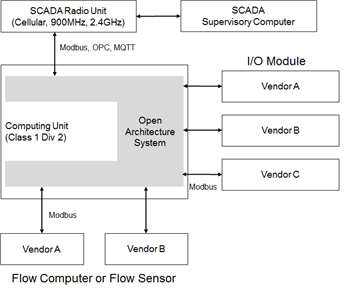

A platform that recognizes and transforms a variety of control protocols and software used in oil & gas fields and other industrial sites

- Main Features

-

A new CPU for an open remote terminal unit (RTU) and applications for wellhead services

Standards establishment and on-site testing for open RTU technology

An open architecture platform that supports a variety of I/O interfaces and communication protocols for RTUs used for industrial purposes

Optimized functions and specifications for oil and gas field services, replacing expensive existing RTUs

- Applications

-

Utility supplyAutomated factory/building control

- Concept

-

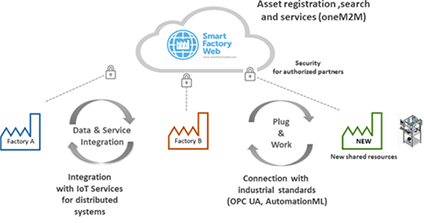

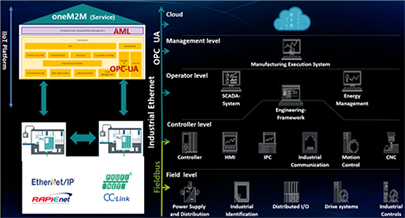

An IoT platform that improves order fulfillment by enabling flexible capacity management and effective resource & equipment sharing

- Main Features

-

Enable optimal resource allocation to the right location, providing flexible custom manufacturing for adaptation to the changing business environment

OPC-UA, AutomationML, and oneM2M-based technologies for factory-to-factory information technology (IT)/operational technology (OT) integration

A safe plug-and-work feature for equipment interoperability and proof of concept (POC) scenarios for intelligent manufacturing data analysis

- Applications

-

Smart factoryFlexible, customized production (speed factory)

Copyright(C) 2016 KOREA ELECTRONICS TECHNOLOGY INSTITUTE., All Rights Reserved.